Hidden behind drywall and tile, small shortcuts can snowball into fires, floods, and fines. In the United States, permits, inspections, and licensed trades exist because past mistakes cost lives and property. Electrical panels, gas vents, and water lines must meet tested standards, not guesswork. A quick fix may look clean in the moment, yet it can void insurance and stall a sale months later. Knowing the legal line protects both safety and equity.

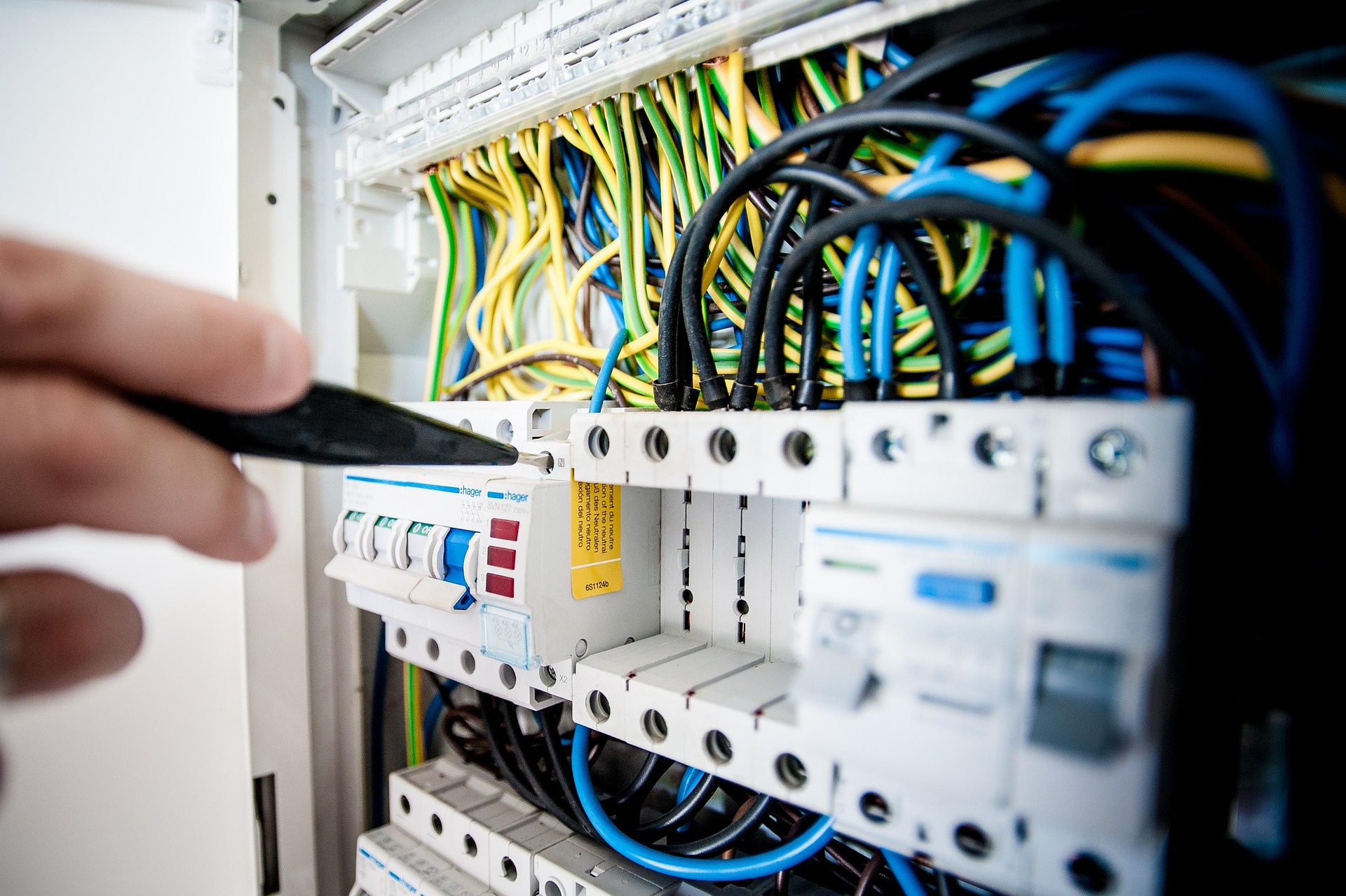

Replacing a Main Service Panel Without a Permit

A panel swap changes the center of the electrical system. Service conductors, grounding and bonding, working clearances, and arc fault coverage all come into play. Utilities may require coordinated shutoffs and meter work. Without permits and inspection, insurance claims after a fire can become a fight. Most jurisdictions expect a licensed electrician for service upgrades and a final signoff. Legal compliance is not red tape. It is the safety baseline.

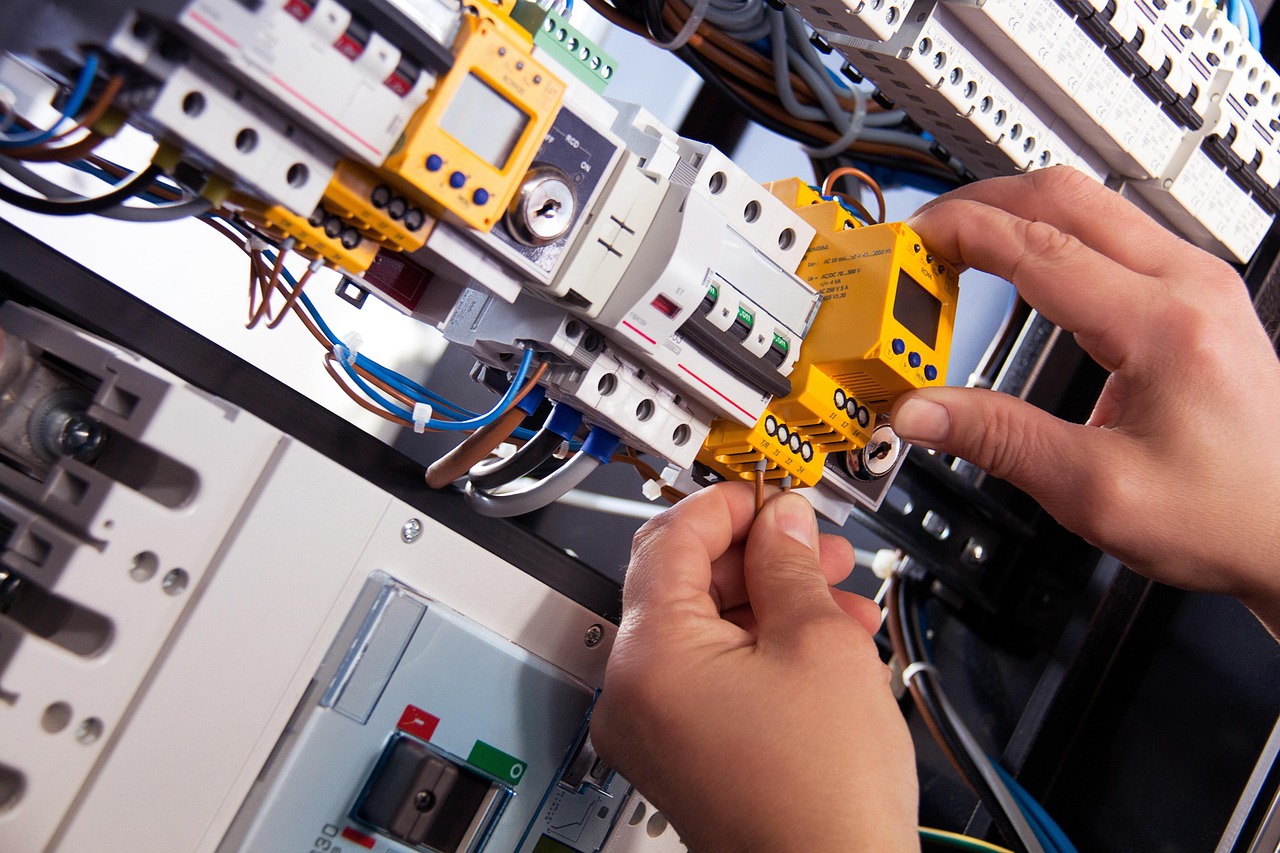

Double Tapping Breakers and Overfusing Circuits

Adding two conductors under a single breaker screw creates loose connections and arcing. Upsizing a breaker to stop nuisance trips lets wires overheat without protection. Both moves violate listings and are easy for inspectors to spot. The correct path is a listed tandem, a subpanel, or a new circuit after a load calculation. The cost feels dull compared with a meltdown in a wall cavity. Good design prevents drama later.

Concealed Junction Boxes and Hidden Splices

Every splice needs a listed box with a cover that remains accessible for life. Burying connections behind new drywall or insulation traps heat and hides failures. Troubleshooting becomes guesswork and emergency shutoffs take longer. During a sale, thermal scans and inspection checklists reveal these shortcuts and force costly reopen and repair work. Accessibility is a life safety rule, not a suggestion. Make every connection visible and serviceable.

Extension Cords as Permanent Wiring or Cheater Adapters

Extension cords are temporary by design. Running them through walls or under rugs invites abrasion, heat, and overload. Adapters that fake a ground without a real equipment ground defeat shock protection. Insurers and inspectors treat long term cord use as a violation, especially on refrigerators and space heaters. The legal solution is a properly routed branch circuit with a listed box, correct cable, and an appropriately sized breaker.

Swapping Outlets Near Water Without Required Protection

Bathrooms, kitchens, basements, garages, and outdoor areas require ground fault protection and often arc fault coverage. Replacing a standard receptacle near a sink without these protections raises shock risk and fails code. Line load mixups can also disable downstream protection without anyone noticing. Permits may be required when circuits are altered or layouts change. The safe route is verifying protection zones and documenting the result at inspection.

Moving Gas Water Heaters or Furnaces Without Proper Venting

Relocation changes vent length, slope, and combustion air. A wrong vent path can backdraft carbon monoxide into living spaces. Drip legs, sediment traps, and clearances must match fuel gas standards. Jurisdictions typically require permits, pressure testing, and final combustion checks. Insurers expect records when fuel burning equipment moves. Legal compliance means listed vent parts, correct sizing, and numbers that prove safe draft and stable operation.

Installing S Traps or Removing Required Vents

Drainage depends on venting to protect trap seals. S traps siphon themselves dry and invite sewer gas. Unvented fixtures or capped vents create slow drains and foul air. Even modest remodels often need permits to verify vent sizing, distances, and cleanout access. Improvised trap arms clog and fail inspection. Fixing the layout after tile is set costs more than doing vents right the first time.

Creating Cross Connections Without Backflow Protection

Cross connections allow polluted water to flow into potable lines. Common offenders include hose ends submerged in buckets, irrigation tie ins without a backflow device, and boilers piped into domestic supply without isolation. Many cities require specific assemblies and periodic testing by certified technicians. Skipping those steps risks public health and brings rapid enforcement. Air gaps or listed devices are the lawful and safest solution.

Routing Sump Pumps or Roof Drains Into the Sanitary Sewer

Sending groundwater or stormwater to a sanitary line overloads treatment systems and violates local ordinances. Municipalities issue fines, demand reroutes, and may inspect neighborhoods after heavy rain. Legal options include discharge to daylight, dry wells, or approved storm lines, with attention to erosion control and property lines. Keep records of permits and inspections. Clear paperwork avoids disputes when selling or refinancing the property.

Replacing Lead, Galvanized, or Main Supply Lines Without Oversight

Upgrading old service lines improves water quality, but material selection, electrical bonding continuity, and utility coordination are tightly regulated. Some cities coordinate partial lead lateral replacements to avoid disturbing contaminated soil without a full plan. Unpermitted work can void warranties and complicate bacteriological test results. The lawful path uses permits, trench notifications, approved materials, pressure tests, and final signoff that travels with the deed.